Non Destructive Tests of welded joints

-

Visual and Measurement Control (VMC)

Performed in a volume of 100% for both the weld and the base material. In many cases, a layer-by-layer visual inspection is carried out during welding. Techniques of carrying out VMC: GOST R ISO 17637-2014, RD 03-606-03 (canceled in 2021, can be used as a reference)

For polyethylene pipelines are guided by: SP 42-103-2003 Appendix N and VSN 003-88 p.7.5.7;Ultrasonic test (UT)

In many cases, it can replace x-ray control. Difficult to use for austenitic steels. Ultrasonic testing is carried out for the base metal and for welds with full filled of the edges.

A document on the technique of carrying out UT - GOST 55724-2013

The separate document is developed for load-lifting mechanisms - RD ROSEK 001-96

For polyethylene pipelines should guided SP 42-103-2003 Appendix R

It should be noted that the control of stainless steels, titanium and other materials, which many consider impossible to control using standard UT-method, can be performed with ultrasonic devices on phased arrays.X-ray inspection (RT)

The most informative inspection method for detecting internal weld defects. As well as UT, RT is applied only to welds with full filled of edges.

A document on the technique of carrying out RT - GOST 7512-82

A separate document has been developed for lifting mechanisms - RD ROSEK 01-002-96

For boiler and steam vessels you can guided RD 34.10.068-91

For vessels and apparatus working under pressure of petrochemical industries can be guided STO 00220368-010-2007Dye penetrantion inspection (DPI)

DPI is often used at the welding seams, where it isn't possible to perform a normal x-ray control or ultrasound control (Filled welds without fully melting edges. DPI is carried out in addition to visual control).

Techniques of carrying out DPI GOST 18442-80, OST 26-5-99Magnetic particle testing (MPT)

The magnetic or magnetic particle testing method, like as color flaw detection (penetration test), is used to search for small surface defects in welds. It is distinguished by the clarity of results presentation with simplicity and versatility of application. The main method limitation is using only for testing parts and seams of steel structures made of ferromagnetic materials with magnetic permeability at least a certain level

The main regulatory document for the magnetic particle testing method: GOST R 56512-2015The vacuuming

The vacuuming is most often used to check for the tightness of the tanks bottom or underground vessels.

The vacuuming is a very effective control method, it is often detect defects that could not be found using Ultrasonic test.

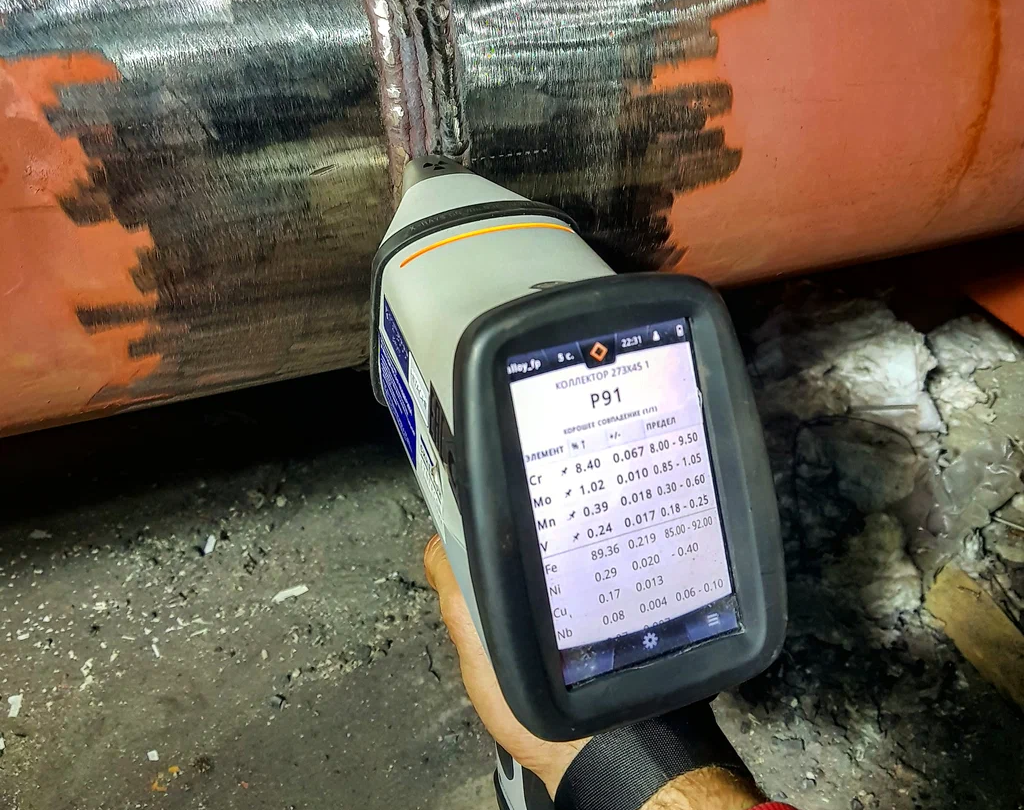

The following seams types can be checked: butt, overhead, taurus. A document on the technique of carrying out the Vacuuming: GOST 18442-80Styloscoping PMI

PMI (Positive Material Identification) - this is a chemical analysis of the weld metal or the main parts material using a portable device.

PMI method allows us to detect the presence / absence of alloying elements and their percent quantity. Which makes it possible to quite accurately detect the brand of material (steel grade). It can be possible to control any details types and any welding seams as well. It applying on the shop and field.

Techniques of carrying out PMI: GOST R 54153-2010, GOST 28033-89Acoustic emission testing

The acoustic emission method (AE) is general used as accompanying for pneumatic test of technological pipelines or vessels. This method can to identify defects in welds, in the material of parts and pipes and shut -off valves when they first appear. Accurately locates air leaks even before pressure reaches the test level. Thus safety in testing is ensured. Also the method is used to diagnose complex technical devices, buildings, structures and their elements, bridges and other objects during industrial safety expertise

The acoustic emission testing technique is described in GOST R 52727-2007Wall thickness ultrasonic test

State estimation of pipelines, tanks or pressure vessels often is performed by measurement of parts wall thickness. For example, it is required to find wall loss during pressure vessel operation with corrosive agents. When ultrasonic wall thickness testing is complete the engineer may decide that repair or replacement of construction elements is required

The principles for ultrasonic thickness measurement is described in GOST R ISO 16809-2015, equipment is used in accordance GOST R 55614-2013Electrospark testing method for continuity testing (EC)

Electrical anti-corrosion coatings testing of pipelines is carried out in order to assess the state of continuity, which determines the pipeline protection quality from aggressive environmental influences (usually for pipelines laid underground, in trenches). Electric spark flaw detectors with spring or brush electrodes are used for testing the paint and varnish coatings continuity also. The equipment is produced by companies: «Buckley», «Elcometer» or «Constant»

Spark testing method is governed by GOST 34395-2018, GOST R 51164-98, the dielectric continuity requirements are shown in GOST 9.602–2016 table 2, 3Coating thickness measurement

Thickness measurement of the coating of pipes, metal parts, products must be carried out before testing for dielectric continuity. Depending on the insulation / paint thickness, select the operating mode of the flaw detector. For measurements, a multifunctional device with various sensors is used (magnetic method). In the same way, you can check the thickness of car paintwork.

The main regulatory document for this control type: GOST 31993-2013 (ISO 2808:2007)Thermal control (TC)

The most common methods are thermal imaging (thermal imager) and thermal monitoring (infrared pyrometers or contact thermometers). Applying to welding processes, this control method is important for maintaining thermal conditions when welding such materials as high-alloy austenitic steels and heat-resistant chromium-molybdenum steels. In general, thermal imagers are used to search for heat loss in buildings, control the heating of electrical wiring, and electrical panel equipment.

Regulatory documents: GOST R 54852-2011, MDS 23-1.2007, NPO M 26.00.00.000Vibrodiagnostic method (VD)

Vibration measurement and evaluation of operating equipment is carried out for the monitoring purpose of the general technical condition and drawing up maintenance plans for machines and mechanisms. When monitoring, inertial type sensors are used, as well as non-contact type displacement sensors. Vibration method can check the condition industrial compressors, motors, fans, turbines, bearings and bearing units

Vibrodiagnostics is regulated by a series of standards: GOST R ISO 7919-1-99, GOST R ISO 7919-4-99, GOST R ISO 10816-3-99, GOST R ISO 10816-4-99, GOST R ISO 13373-1-2009, GOST R ISO 13373-3-2016, and GOST ISO 2954-2014, GOST 30576-98Incoming inspection

Incoming inspection is a comprehensive assessment of products and building materials that enter the installation sites or production. In large organizations (or factories) such control is carried out by specialists of the Incoming control department. According to the accompanying and technical documentation, the volumes and types of control of each batch of materials are determined, equipment or accessories. Also, in order to ensure the impartiality of checking the quality of material assets, independent non-destructive testing laboratories are involved and testing.

-

The technical devices groups are not only different structures types, but also various normative documentation for quality assessment

Steel Structures [SK-1]

For welded seams of steel structures are most often used next NDT methods:

VT, UT, DPI, seldom - Vacuum method.

To determine the control volume you need should be guided of the project requirements or Russian regulatory documentation: GOST 23118-2019 p.6.4, table 4; SP 70.13330.2012 p.10.4, table 10.6

The quality welds assessment is carried out according to the next Russian standards: GOST 23118-2019 p.5.5, Appendix А; SP 70.13330.2012 p.10.4; OST 36-60-81 p.6, p.7, tables 6, 8, 9; RD 34.15.132-96 p.5, p.8.2, tables P14.1 ... P14.4Reinforcement details (reebars) [SK-2]

Reinforcement details are inspected only by Visual and Ultrasonic control methods. In addition, mechanical tests of both rods and welded samples are carried out.

Weld construction - according GOST 14098-2014 or RTM 393-94

Welded joints quality control - according RTM 393-94 part II, p.3, p.5.5, GOST 14098-2014 and GOST Р 57997-2017 section 5Steel pipes (water pipelines, sewerage, heating pipes, ducts) [SK-3]

These pipelines are not classified as technological, don't have categories and groups. But they are found not only in civil construction, but also in industrial facilities (underground pipelines).

These pipelines are often made of carbon, low alloyed and stainless steels.

Types of non-destructive testing: Visual, RT, UT, DPI, PMI

Design of welded joints - according GOST 16037-80, RD 153-34.1-003-01 (RTM-1C)

Welded joints quality control - according: SP 73.13330.2016 (SNiP 3.05.01-85) section 5, SP 74.13330.2011 (SNiP 3.05.03-85) p.5.16...p.5.26, SP 129.13330.2011 (SNiP 3.05.04-85) p.3.36...p.3.43, RD 153-34.1-003-01 (RTM-1C) p.18.2...p.18.6, p.7.7.2Polyethylene pipelines [SK-4, GO-2p, OHNVP-16p]

Polyethylene and gas pipelines are laid underground. The most popular 2 welding methods: Fittings with embedded heaters (electro-fusion) and welding with heated tools (butt-fusion).

Non-destructive testing methods: Visual and Ultrasonic

Standards should be followed to assess the quality for PE water pipelines, sewerage and process pipelines:

VSN 440-83 p.7, SP 40-102-2000

For gas pipelines and as additional standards for the other PE pipelines apply

SP 42-103-2003 p.8.11...p.8.30, GOST R 55473-2013 section 7Cranes [PTO-1, PTO-7, PTO-14]

General name for a subclass of hoisting machines intended for the carriage of goods, the temporary engagement of which was carried out with the use of various load-handling devices: hook hangers, load-handling bodies of a special design.

Non-destructive testing methods: VT, RT, UT and DPI

When conducting control, it is necessary to be guided by regulatory documentation:

RD ROSEK-004-97, GOST 34587-2019, RD 24.090.97-98

The following standards are required for quality assessment:

RD ROSEK-004-97 p.12, GOST 34587-2019 p.6.3, RD24.090.97-98 p.5.3...p.5.5

Steam and hot water pipelines [KO-2]

Steam and hot (overheated) water pipelines - pipelines designed to transport water vapor with an overpressure of more than 0.07 MPa or water at a temperature of more than 115°С (including pipelines of heating networks and other purposes) for the purpose of transferring thermal energy.

When inspecting pipeline welds, methods are used: VT, RT, UT and DPI

The design of welded joints - according to RD 153-34.1-003-01

Assessment of the quality of welds - according to RD 153-34.1-003-01 p.18.3...p.18.5,p.18.8, RD-2730.940.103-92 p.10.9, p.10.5Gas pipelines of low, medium and high pressure [GO-1, GO-2]

Any existing gas supply system consists of two main parts: gas transmission and gas distribution. The gas transportation system includes main gas pipelines, underground gas storages (UGS), compressor (pumping) stations and control system (including the necessary fittings).

Control methods: VT, RT, and UT

When inspecting welded seams of gas pipelines, it is necessary to be guided by regulatory documentation: СП 62.13330.2011, RD 153-34.1-003-01, SP 42-102-2004

The following standards are required for quality assessment:

SP 62.13330.2011 p.10.2, p.10.4, SP 42-102-2004 p.7.97...p.7.99, SP 153-34.1-003-01 (PTM-1c) tabl.18.10, tabl.18.11Equipment for chemical, petrochemical and oil refining industries [OHNVP-1, OHNVP-2, OHNVP-3]

Vessel - a hermetically sealed container (permanently installed or movable) intended for conducting chemical, thermal and other technological processes, as well as for storage and transportation of gaseous, liquid and other substances.

Suitable for all equipment non-destructive testing methods

To determine the scope of control, you need to be guided by the requirements of the project or regulatory documentation: GOST 34347-2017

The quality of welds is assessed according to the standards GOST 34347-2017 p.5.10, p.5.10.3, p.5.10.2, chap.7.8, p.7.6, p.7.7,

OST 36-50-86, STO 00220368-019-2011Storage tanks for explosive and toxic substances, oil storage tanks [OHNVP-4, NGDO-5]

They are used to store substances of hazard class 1-4: flammable, chemically aggressive and neutral liquids, food products, drinking and industrial water.

All are suitable for tanks. non-destructive testing methods

The design of welded joints - according to GOST 31385-2016

For tanks PIC "Transneft" a regulatory document is required - RD-25.160.10-KTN-015-15

Quality assessment - by GOST 31385-2016 p.9.3.5-9.3.11, p.9.4.5, p.9.5.6, p.9.5.9, STO SA 03-002-2009 with ID-2010 p.19.4.3, p.19.7.4, p.19.7.2.2, p.19.7.3

Cryogenic equipment, ammonia refrigeration equipment [OHNVP-6, OHNVP-7]

Cryogenic equipment is used to store, pump and transport liquid gases that require low temperatures to maintain their state. To do this, the devices are equipped with a good thermal insulation and tools for creating and maintaining temperatures from -120ºC.

Control methods: VT, RT, DPI and UT

To determine the scope of control of cryogenic equipment and refrigeration plants, it is necessary to be guided by the regulatory documentation: GOST R 54892-2012

To define quality control scopes: GOST R 54892-2012 p.9.17, p.9.18

Waste heat boilers, energy technology boilers, boilers BOC [OHNVP-12, OHNVP-13, OHNVP-14]

Waste heat boilers do not have all the elements that are typical for fuel-burning boilers, in particular, burners and fuel preparation and supply systems. There is no air heater and a furnace in the waste heat boilers, since the gases used in the boiler are formed in the technological process of the main production.

Control methods: VT, RT, DPI and UT

The design of welded joints - according to STO 38.17.003.2009, RD 26-02-8-2004

Quality assessment - by STO 38.17.003.2009, РД 26-02-8-2004 p.3.8.4.5, tabl.6, p.3.8.3

Process piping and pipeline details [OHNVP-16, MO-2]

Technological pipelines are sets of pipes and equipment used to transport technical substances and liquids in industrial enterprises and facilities. They are used to transport various raw materials, intermediate and final products of industrial production, waste and other substances involved in the production process, as well as substances necessary for the operation of facilities.

Control methods: VT, RT, DPI and UT

To determine the scope of control, it is necessary to be guided by the requirements of the project or regulatory documentation: GOST 32569-2013

Quality assessment - by GOST 32569-2013 p.12.3.10...p.12.3.12, tabl.12.2, tabl.12.4, tabl.12.5, STO 38.17.003.2009Technical devices (mining, mining and processing facilities and underground facilities [GDO-1]

Mining equipment is used to develop mineral deposits in mines and quarries. It includes a set of technologically sophisticated installations that help automate the performance of basic and auxiliary operations: from breaking, loading and transporting rock mass to backfilling

Control methods: VT, РT, UT and DPI

The design of welded joints - according to RD 34.15.132-96, GOST 23118-2012

Assessment of the quality of welded joints - according to RD 34.15.132-96 p.8.1, p.8.2, GOST 23118-2012 p.5.7.4, p.6

Cisterns, cylinders for explosive and toxic substances[OTOG-2, OHNVP-11]

Tanks for dangerous goods are specialized containers made on the basis of composite materials that meet modern quality, reliability, safety and tightness requirements. Metal containers have been replaced by fiberglass ones, which are famous for their great advantages

Control methods: VT, РT, UT and DPI

The design of welded joints - according to GOST 33976-2016, OST 24.050.34-84, DOPOG tome-II p.6.2.1.5, p.6.8.2.1.23

Assessment of the quality of welded joints - according to GOST 33976-2016 p.7, GOST R ISO 10042-2009, tabl.1 quality level CMetal structures of superstructures of supports and pylons of steel bridges [KSM-1, KSM-2]

Bridges are called steel, the main spans of which are made of steel. Their supports can be made of concrete, reinforced concrete and other materials. Construction steels have high strength, ductility and toughness, so steel bridges have the largest spans and operate reliably under heavy dynamic loads.

Control methods: VT, UT

Quality assessment according to STO-GC "Transstroy" 005-2018 p.10.19, p.10.20, p.12.7, tabl.15, tabl.16, p.10.23, p.10,24; application I3---I8Field and main oil product pipelines, pipelines of oil pumping stations [NGDO-1, NGDO-2], process pipelines of oil pumping stations [NGDO-4]

Field pipelines are designed for a long service life and are designed for uninterrupted transportation of natural gas, oil, petroleum products, water and their mixtures from production sites to complex treatment facilities.

Welds of such pipelines are subject to 200% volume control: VT, RT + UT, DPI color test

At "Transneft" PJSC facilities, welding and inspection of welded joints is carried out in accordance with the organization’s internal standards: RD-25.160.00-KTN-037-14; RD-25.160.10-KTN-016-15; RD-03.120.10-KTN-007-16

To determine the control scope at other facilities, you need to be guided by the project requirements or next regulatory documentation: SP 406-1325800.2018; SP 86.13330.2014; VCN 006-009; VCN 012-88

Quality assessment according to: SP 406-1325800.2018 p.9.5, p.9.6, p.9.7, p.9.8, p.9.9, p.9.10; SP 86.13330.2014 p.9Field and main gas pipelines and condensate pipelines; pipelines for transportation of marketable products [NGDO-3], process pipelines of gas pumping stations [NGDO-4]

A condensate pipeline is a pipeline designed to transport gas condensate from a production site to processing and a consumer. By design, it is similar to the main pipeline, where pumping units are used to pump substances. It consists of pipes, shut-off and control valves, retaining tanks, measuring and control equipment. Belongs to the category of responsible systems.

Control methods: VT, RT, UT and DPI

On objects PIC "Gazprom" welding and control of welded joints are regulated by the internal standards of the organization: STO "Gazprom" 2-2.2-136-2007, 2-2.3-136-2007, 2-2.2-115-2007, STO Gazprom 2-2.2-649-2012; RD 51-31323949-38-98

On other objects - to СП 86.13330.2014

Assessment of the quality of welded joints at facilities PIC "Gazprom" carried out with the help: STO "Gazprom" 2-2.4-083-2006

On other objects - to SP 86.13330.2014 p.9Pipelines of automated gas filling compressor stations (AGFCS) [NGDO-13]

AGFCS — this is an automobile CNG filling compressor station. In simple words, CNG stations supply gas and similar materials instead of fuel. Such compressor stations can provide gas to any type of transport. They are able to work even with the equipment that is designed to work with methane.

Control methods: VT, RT, UT

Regulatory documentation for the control of welded joints: On objects PIC "Gazprom"- STO Gazprom 2-2.1-607-2011. On other objects - GOST 32596-2013

Assessment of the quality of welded joints at facilities PIC "Gazprom": STO Gazprom 2-2.1-607-2011. On other objects - GOST 32596-2013 p.12.3

![Steel Structures [SK-1]](/img/ndt/steel-struct-1.jpg)

![Reinforcement details (reebars) [SK-2]](/img/ndt/reebars.jpg)

![Steel pipes (water pipelines, sewerage, heating pipes, ducts) [SK-3]](/img/ndt/steelwaterpipes.jpg)

![Polyethylene pipelines [SK-4, GO-2p, OHNVP-16p]](/img/ndt/pe-pipes.jpg)

![Cranes [PTO-1, PTO-7, PTO-14]](/img/ndt/lifting-crane.jpg)

![Steam and hot water pipelines [KO-2]](/img/ndt/steam-and-hot-water-pipelines.jpg)

![Gas pipelines of low, medium and high pressure [GO-1, GO-2]](/img/ndt/gas-supply-pipeline.jpeg)

![Equipment for chemical, petrochemical and oil refining industries [OHNVP-1, OHNVP-2, OHNVP-3]](/img/ndt/ohnvp1-2-3.jpg)

![Storage tanks for explosive and toxic substances, oil storage tanks [OHNVP-4, NGDO-5]](/img/ndt/storage-tanks-for-toxic-substancse.jpg)

![Cryogenic equipment, ammonia refrigeration equipment [OHNVP-6, OHNVP-7]](/img/ndt/kriogen-oborud.jpg)

![Waste heat boilers, energy technology boilers, boilers BOC [OHNVP-12, OHNVP-13, OHNVP-14]](/img/ndt/waste-heat-boilers.jpg)

![Process piping and pipeline details [OHNVP-16, MO-2]](/img/ndt/technological-pipelines.jpg)

![Technical devices (mining, mining and processing facilities and underground facilities [GDO-1]](/img/ndt/mining-equipment.jpg)

![Cisterns, cylinders for explosive and toxic substances[OTOG-2, OHNVP-11]](/img/ndt/dangerous-goods-tank.jpg)

![Metal structures of superstructures of supports and pylons of steel bridges [KSM-1, KSM-2]](/img/ndt/metal-bridge.jpeg)

![Field and main oil product pipelines, pipelines of oil pumping stations [NGDO-1, NGDO-2], process pipelines of oil pumping stations [NGDO-4]](/img/ndt/main-pipelines.jpg)

![Field and main gas pipelines and condensate pipelines; pipelines for transportation of marketable products [NGDO-3], process pipelines of gas pumping stations [NGDO-4]](/img/ndt/gas-pipeline.jpg)

![Pipelines of automated gas filling compressor stations (AGFCS) [NGDO-13]](/img/ndt/pipelines-agfcs.jpg)