Mechanical testing of steel samples

-

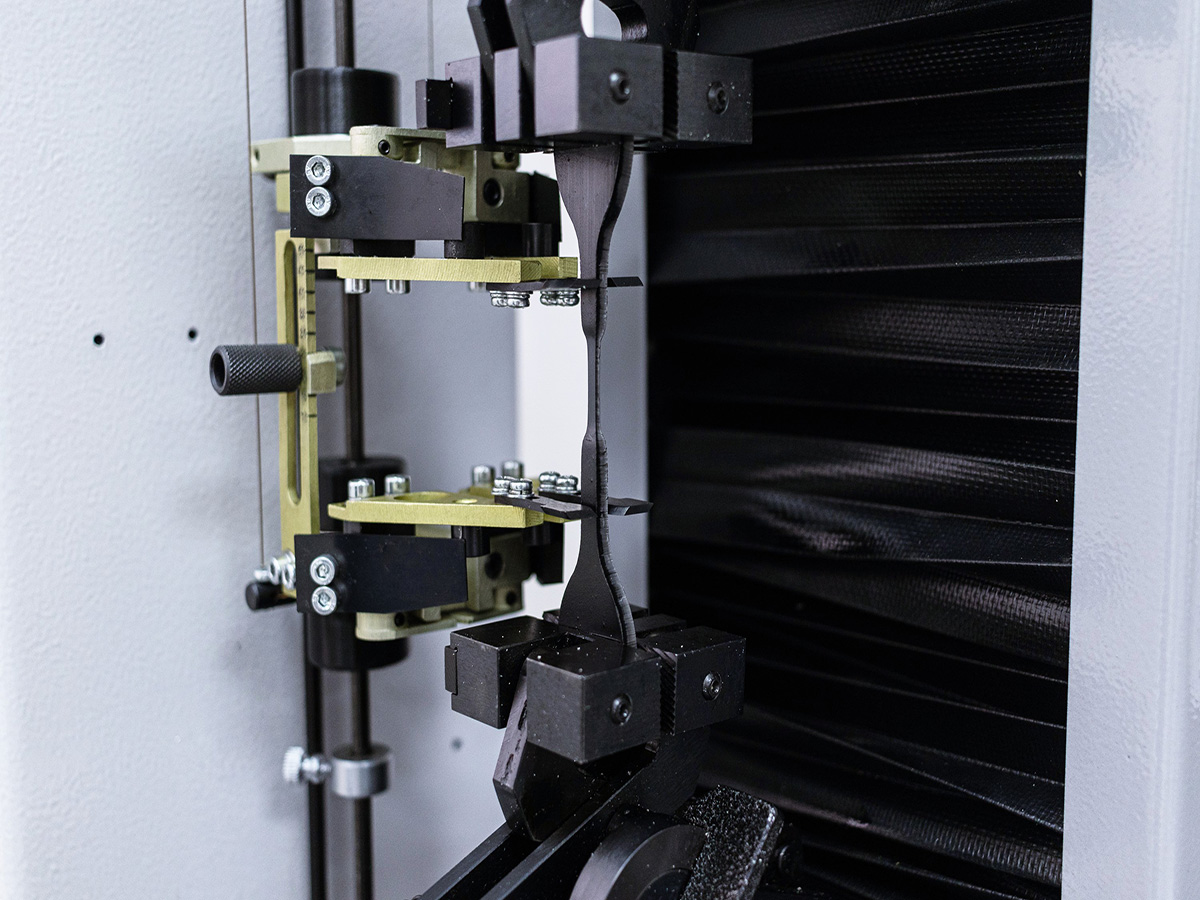

Tensile test

Tensile test - the most common destructive testing method.

This is carried out both for the base material and for welded joints samples.

It is applicable to all groups of devices and various types of materials (metals, plastics, etc.).

Regulatory documentation:

• GOST 6996-66 - Welded joints. Methods for determining mechanical properties;

• GOST R ISO 4136-2009 - Welded joints. Tensile tests of samples cut across the seam;

• GOST 1497-84 (ISO 6892-84) - Metals. Tensile tests;

• GOST 9651-84 - Metals. Methods of tensile testing at elevated temperatures;

• GOST 11701-84 - Metals. Tensile testing methods for thin sheets and tapes;

• GOST 28870-90 - Steel. Methods of tensile testing of thick rolled products in the direction of thickness;

• GOST 10006-80 - Metal pipes. Tensile test method;

• GOST 19040-81 - Metal pipes. Method of tensile testing at elevated temperatures;

• GOST 10446-80 - The wire. Tensile test method;

• GOST 11262-2017 - Plastics. Tensile testing method;

• GOST 34370-2017 - Plastics. Determination of mechanical properties under tension;

• GOST R 57997-2017, GOST 34227-2017, RTM 393-94 - welded joints of reinforcing and embedded parts for concrete structuresStatic bend

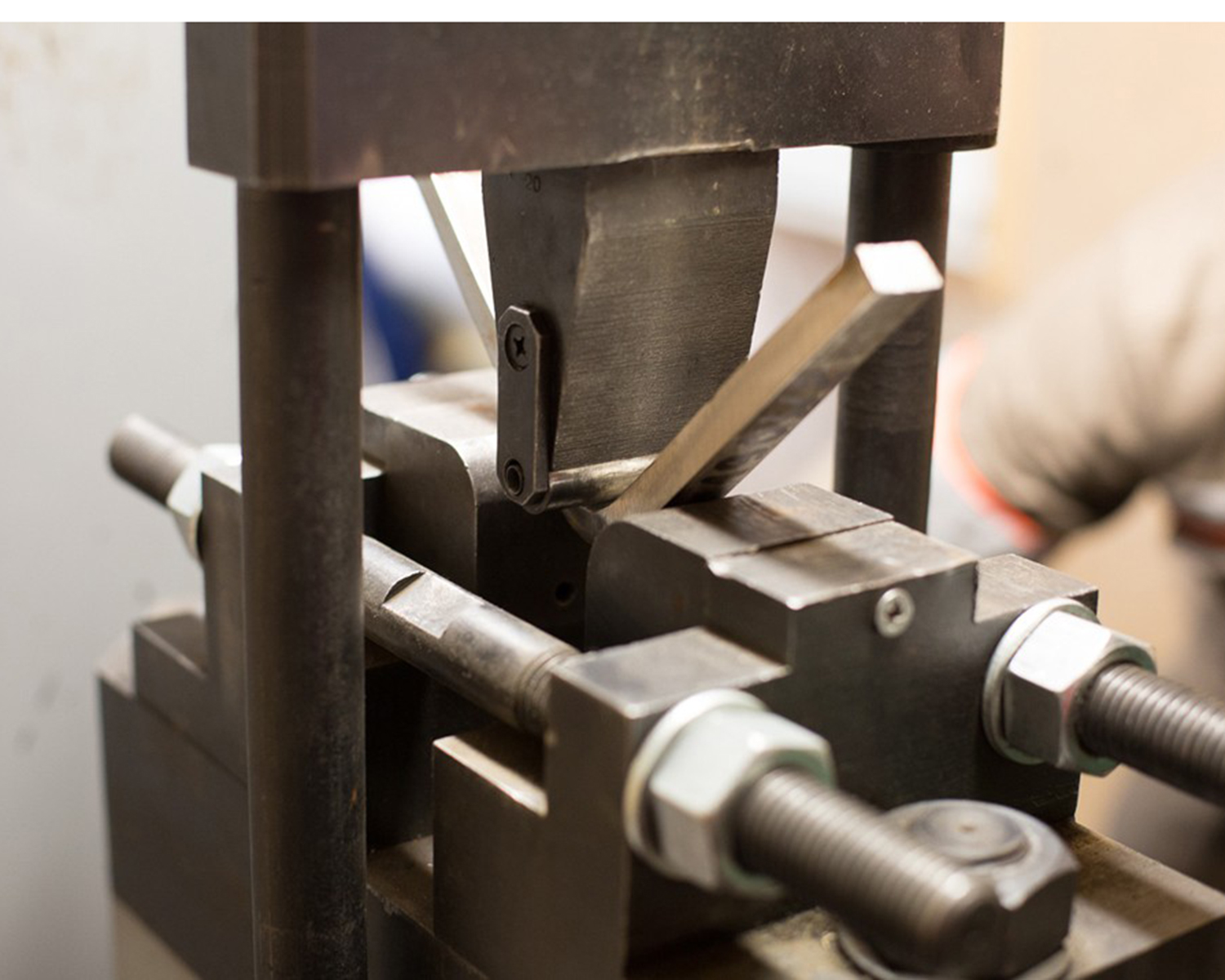

Bending tests are used to assess the ultimate ductility of metals and welded joints or their ability to withstand plastic deformation. In the first case, a given bending angle is obtained, in the second, the test is carried out until the first crack formation on the sample. The welded joints properties are checked on the templates (metal strips cut of across the welding seam), while the bend can be directed by the seam root or the seam face outward, or the bend by the weld side. The requirements and test methods for static bending are described in GOST 6996-66, GOST 14019-2003 (ISO 7438:1985)

Flattening

Can be used as alternative test methods for pipe material or test coupons. The flattening results evaluate the metal ductility of the pipe or transverse weld, like as in static bending. For testing, samples are used in the form of a full-section pipe segment with a length of 10 to 100 mm. Tests are carried out according to GOST 8818-73, GOST 8695-2022

Bending, distribution, beading

Technological tests for bending, expanding and beading are used to assess the pipes quality before their use in production (pipeline welding) or manufacture of fittings from the pipes (bends, tees, bends, transitions). Samples are subjected to the same technological operations as during processing. Based on the test results, conclusions are drawn about the suitability of pipe semi-finished products to use. Tests are regulated by the relevant GOST: for bending - GOST 3728-78; or distribution - GOST 8694-75; on board - GOST 8693-80

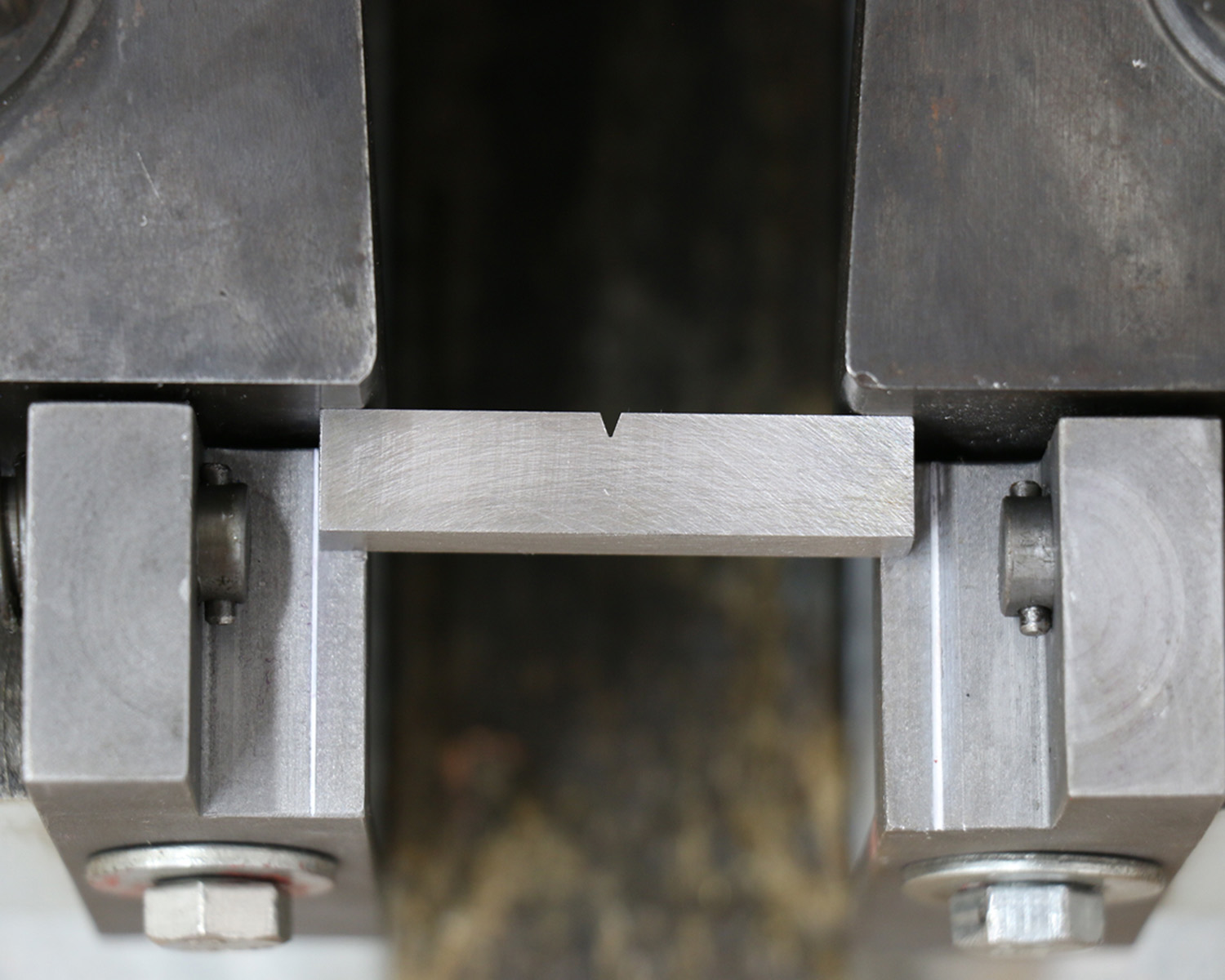

Impact bend

Impact bending (determination of impact strength or Sharpy test) refers to dynamic tests. Such tests make it possible to obtain mechanical characteristics under conditions close to real ones. (as opposed to static methods) and in which metals become brittle, for example, due to the action of stress concentrators or low temperatures. According to the test results, we can determine cold brittleness, thermal brittleness, as well as brittleness of recrystallization and other properties of the material. Impact testing is especially important for welded joints operating at low temperatures. Normative documents: GOST 9454-78, GOST 6996-66, GOST 30456-97, GOST 22848-77

Steeloscopy

Spectral analysis of the chemical composition of a material or optical emission is a method for the most complete and accurate determination of the elemental composition of metallic materials. The analysis is usually carried out on specially prepared samples of materials on stationary equipment in the laboratory. The results of the analysis, in contrast to the X-ray fluorescence method, allow you to determine not only alloying elements, but also the percentage of carbon (C) in steels, the presence of harmful impurities: phosphorus (P), sulfur (S), nitrogen (N) starting from the minimum concentrations

Control methods described in RD 26.260.15-2001, RD 34.10.122-94Hardness

Hardness is determined by the standard methods of Brinell, Rockwell or Vickers. Hardness testing is the process of statically pressing a hard tip into a specimen that has a flat surface. The differences between the methods are in the shape and material of the indenter: according to Brinell - a hardened steel ball, according to Rockwell - a diamond cone, according to Vickers - a diamond pyramid with a square base. In addition to static methods, there are dynamic (method of elastic rebound of the striker, according to Shore) and ultrasonic methods for measuring hardness. Normative documents for testing: GOST 9012-59, GOST 2999-75, GOST R ISO 6507-1-2007, GOST 9013-59

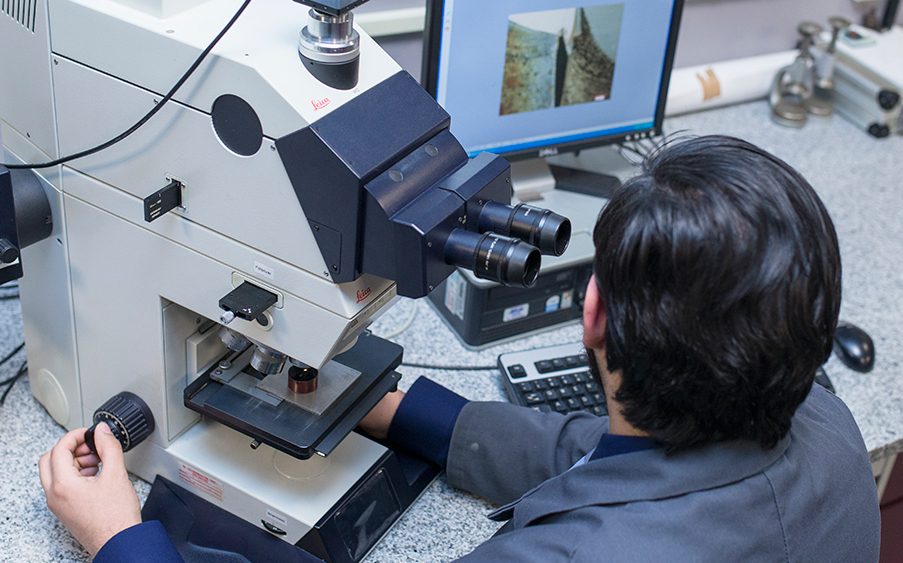

Metallography

Metallographic studies of metals, alloys and welds are carried out in the laboratory on cut and prepared samples (depending on the material, the samples surface can be ground and/or etched). As a result of studying the macro and microstructure, internal defects and discontinuities are revealed. According to the type, type and size of grains, conclusions can be drawn about the complex of physical and mechanical properties of the material, as well as about the factors that affect their change. Metallography is carried out according to the following regulatory documents: GOST 10243-75, GOST 5639-82, GOST 57180-2016, GOST 1778-70, RD 24.200.04-90, GOST 5640-2020

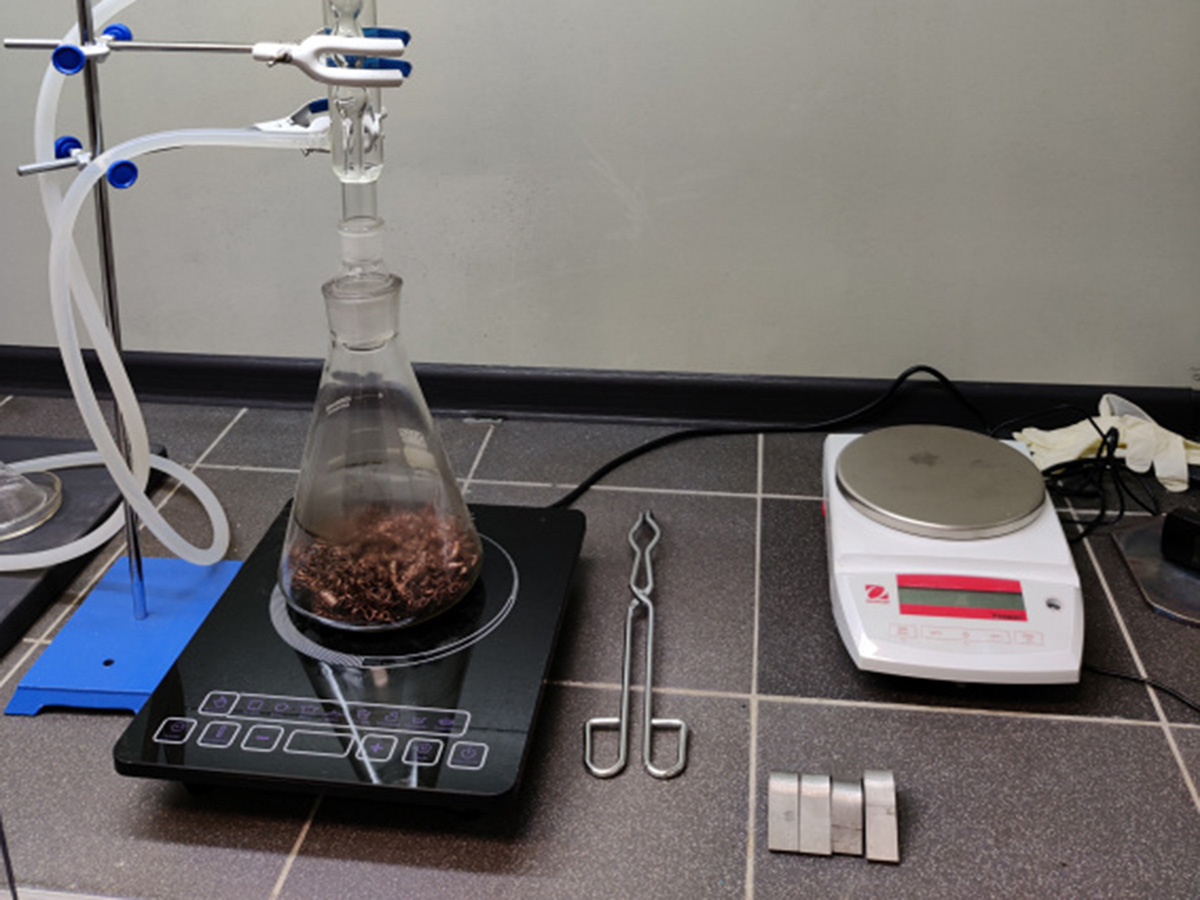

Resistance to intergranular corrosion (ICC)

Intergranular corrosion is one of the most dangerous types of destruction of metals and alloys, due to the fact that it does not show noticeable signs on the surface of the material. Its causes may be: thermal effects of processes welding or other types of processing, as well as violation of cycles and heat treatment modes. ICCs are mainly inclined to stainless austenitic steels (12X18H10T), steels alloyed with molybdenum, copper and containing more than 13% chromium. The test for resistance to ICC is carried out according to the following regulatory documents: GOST 6032-2017, ISO 3651-1:1998, ISO 3651-2:1998

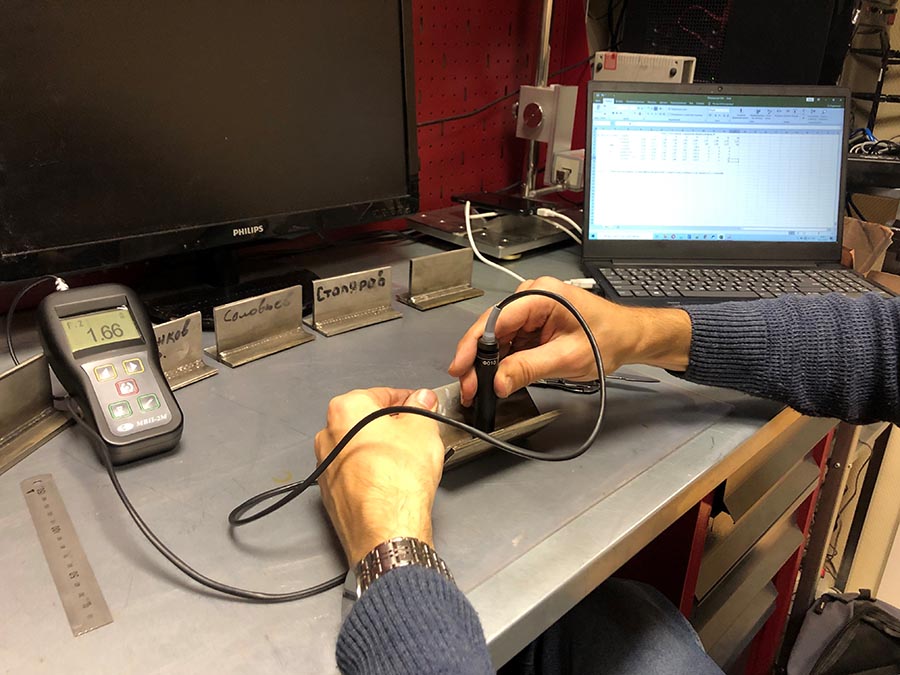

Determination of the content of the ferrite phase

The properties of any steel, especially high-alloy steel, depend on its structural composition. The presence and content of various structures determines, for example, corrosion resistance, mechanical strength and other characteristics. In this regard, for austenitic, ferritic and austenitic-ferritic steels, the percentage ratio of the content of structural phases is normalized. To control the volume of the ferrite phase, special devices are used - magnetic ferritometers. When conducting control, they are guided by the requirements GOST R 53686-2009, GOST 11878-66

Testing of polyethylene pipes, plastics, thermoplastics and their compounds

During the construction of pipelines from non-metallic materials (most often from polyethylene), it is also required to check the strength of welded joints. For welded joints of gas pipelines, the following are used: axial tensile test (Butt Fusion Welds), flattening of coupling joints and separation of saddle bends (Electro Fusion Welds). Additionally, there are special methods: static bending test, long-term tensile test (Butt Fusion Welds), impact resistance test (Electro Fusion Welds for saddles), test at constant internal pressure (Electro or Butt Fusion Welds) SP 42-103-2003, SP 40-102-2000, SP 62.13330.2011 (SNiP 42-01-2002), GOST 11262-2017, GOST 18599-2001, GOST R 53652.1-2009, GOST R 53652.2-2009, GOST R 53652.3-2009, GOST R 58121.2-2018 (GOST R 50838-2009), GOST ISO 1167-1-2013